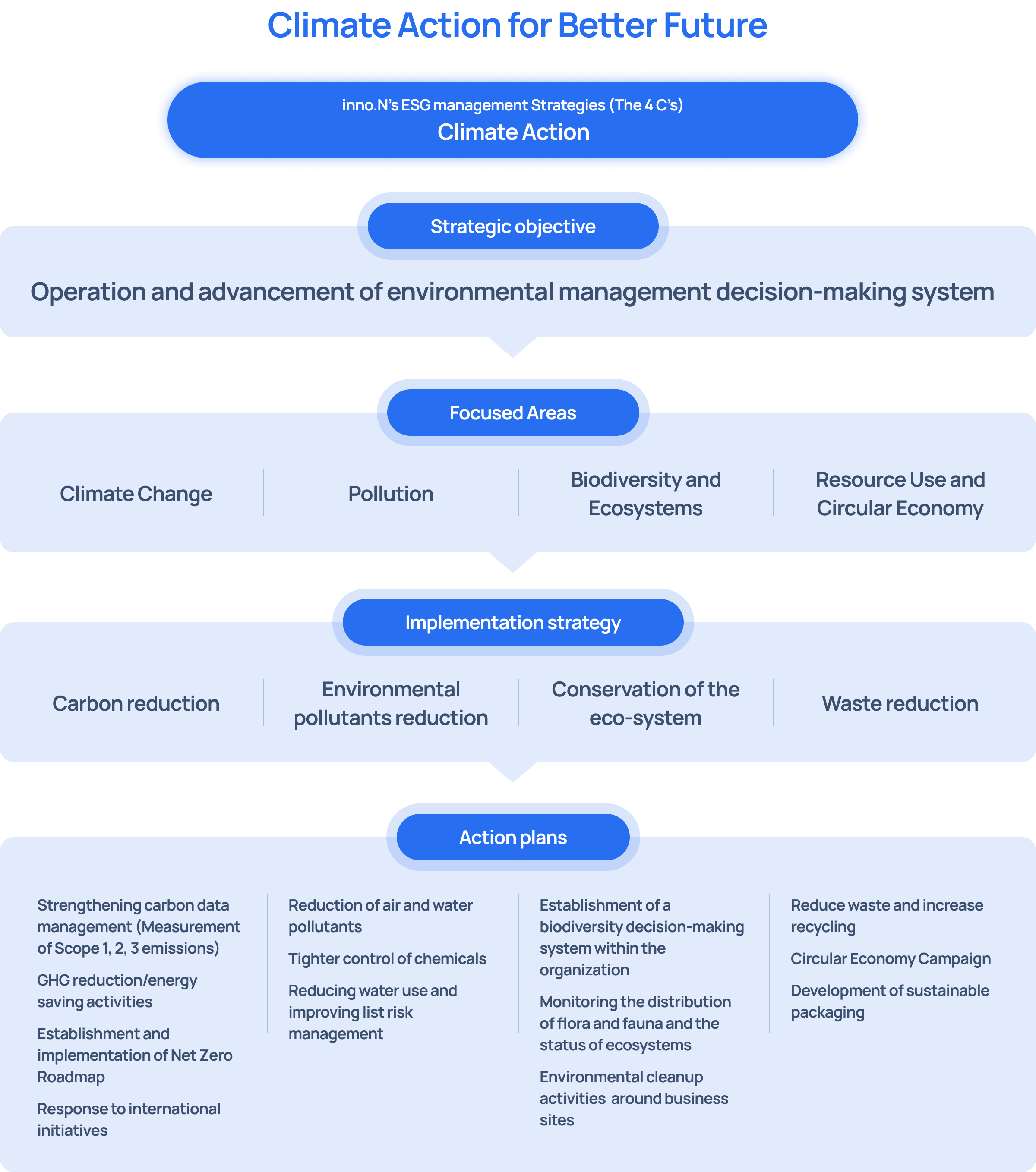

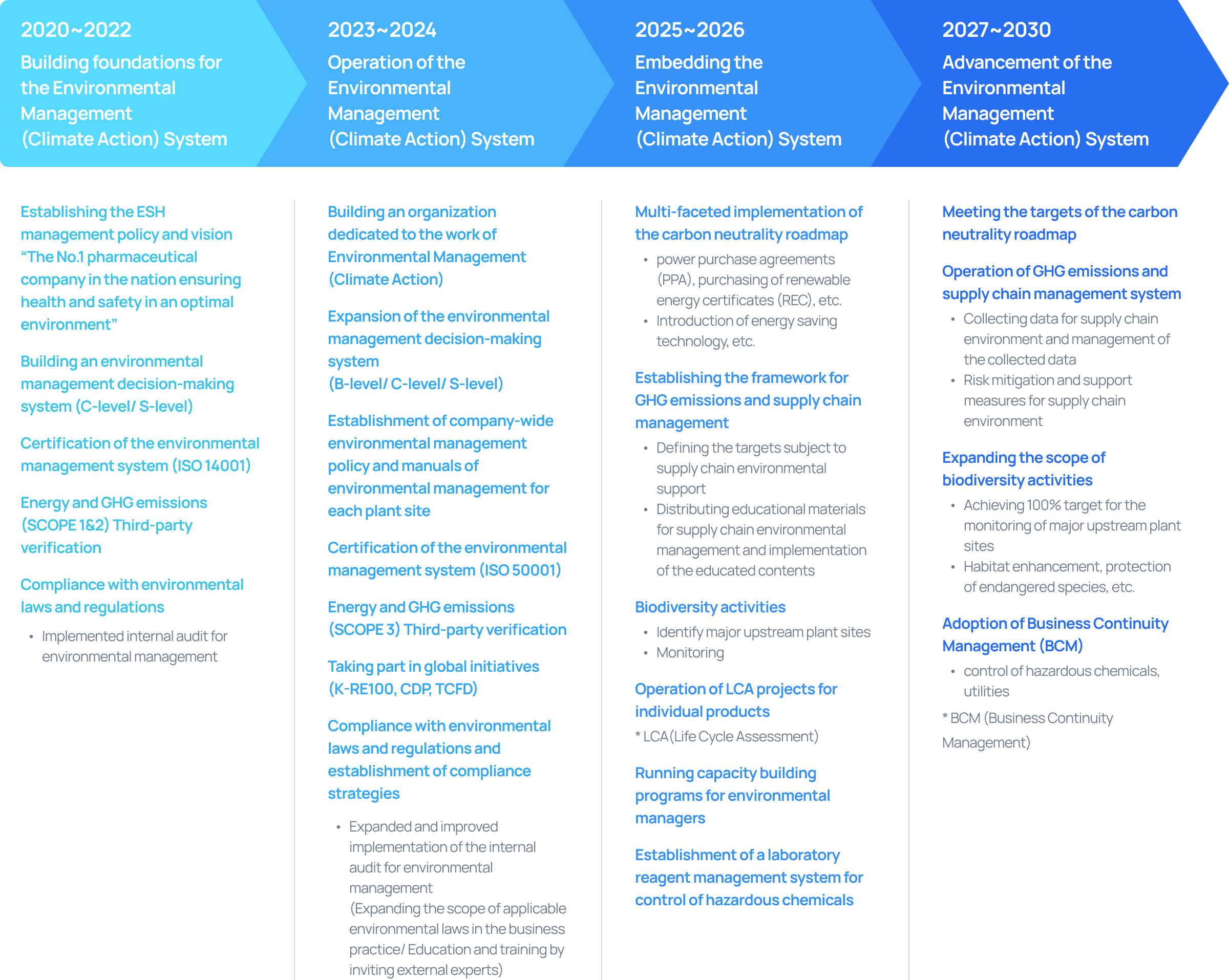

Environmental Management

Business strategy and systems for Environmental management

Environmental Management Goals

Key achievements in environmental management

-

Climate ChangeGHG emissions inventory building (Scope 1&2,3)

measurements and verification

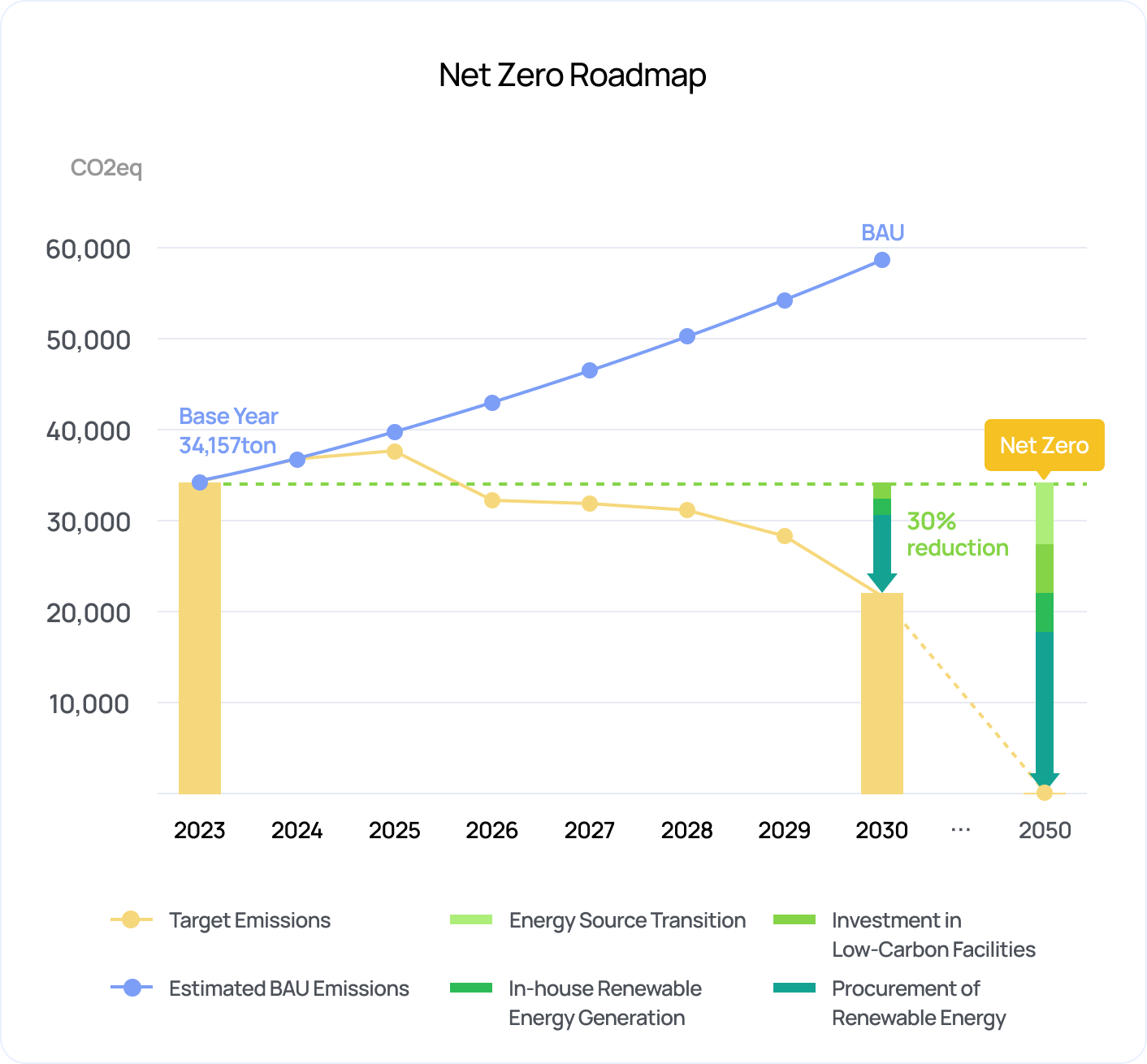

Establishment of the carbon neutrality roadmap

Disclosure according to TCFD recommendations -

PollutionImprovement of air pollutant emission and water contaminant discharge performance

Built water reuse facilities

Increased water reuse (%) -

Biodiversity and EcosystemsRevised biodiversity policy

Implemented monitoring of flora and fauna distribution and ecosystem status around the business sites -

Resource Use and Circular EconomyIncreased waste recycling rates

Used less and lighter plastic packaging

Climate Change

Established the carbon neutrality roadmap to achieve net Zero (zero GHG emissions) by 2050

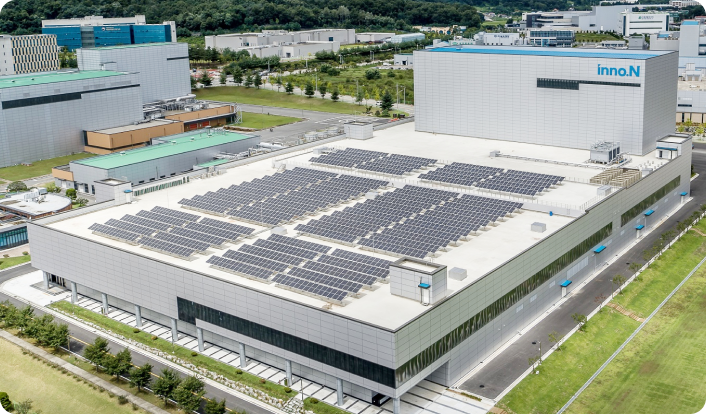

Joined K-RE100, a voluntary initiative to achieve the target of 100% conversion of business power to renewable energy by 2050

Minimization of

Environmental Impact

Biodiversity and Ecosystems

Monitoring distribution of species around the HK inno.N’s plant sites and those of the partner companies and the status of proximity to the protected areas

- Identifying the location of plant sites directly run by HK inno.N and those of major partner companies

- Identification of species with a special focus on endangered species Class I and Class II in the administrative districts where the individual plant sites are located

- Identification of endangered species listed in the CITES Appendices and in the Korean Red List of Threatened Species

(Photos: Prepared by the Natural Monument Division and Conservation Policy Division, divisions in charge of the Korea Heritage Service website of Korea)

Implementing ecosystem conservation activities such as forest restoration through tree planting, eradication of invasive species, and community environmental cleanup activities

Resource Use

and Circular Economy

Inhouse campaigns for employees such as campaign to eradicate disposable cups, Zero food waste campaign, etc.

Promoting 3R (Recycle, Reduce, Reuse) strategy to minimize resources used in packaging of products.

| Strategy | Recycle | Reduce | Reuse |

|---|---|---|---|

| Actions | Use of green materials Improving recyclability |

Lighter packaging Minimizing the use of plastic |

Reuse of packaging |

| Implementation details | Expanded use of eco-friendly packaging (cartons) Tear tapes applied Use of packaging that allows separated disposal |

Expanding the product ranges applying manual pack Sustainable shrink films Use of lighter pads |

Launching products designed for refills for reuse of applicators |

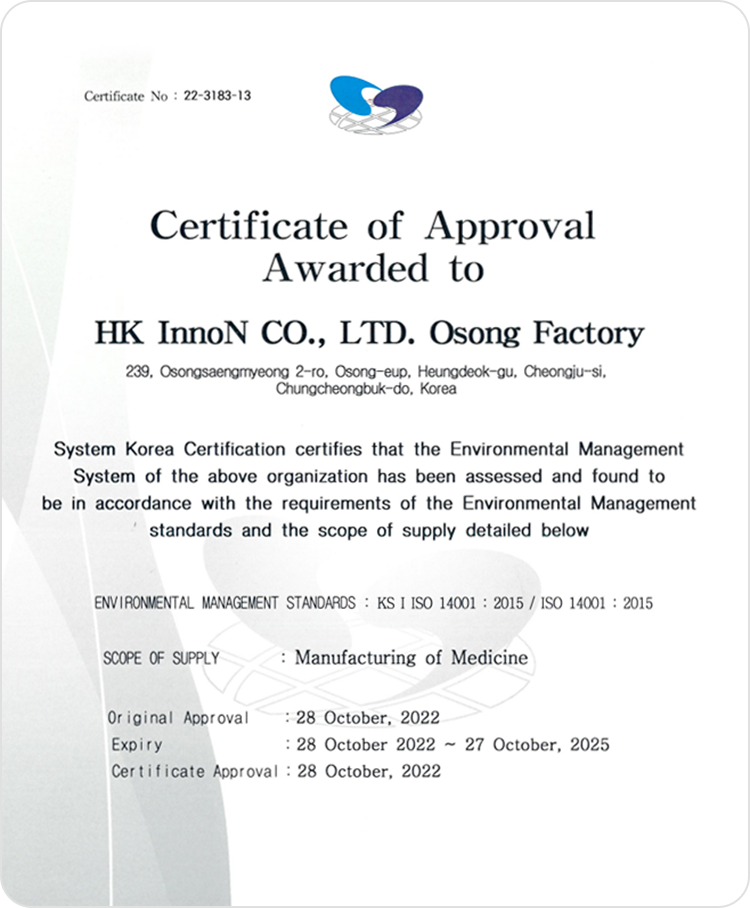

Certification for environmental management

-

[Osong] ISO 14001

Certifications acquired

Certifications acquired

-

[Daeso] ISO 14001

Certifications acquired

Certifications acquired

-

[Icheon] ISO 14001

Certifications acquired

Certifications acquired

-

[Daeso] ISO 50001

Certifications acquired

Certifications acquired

-

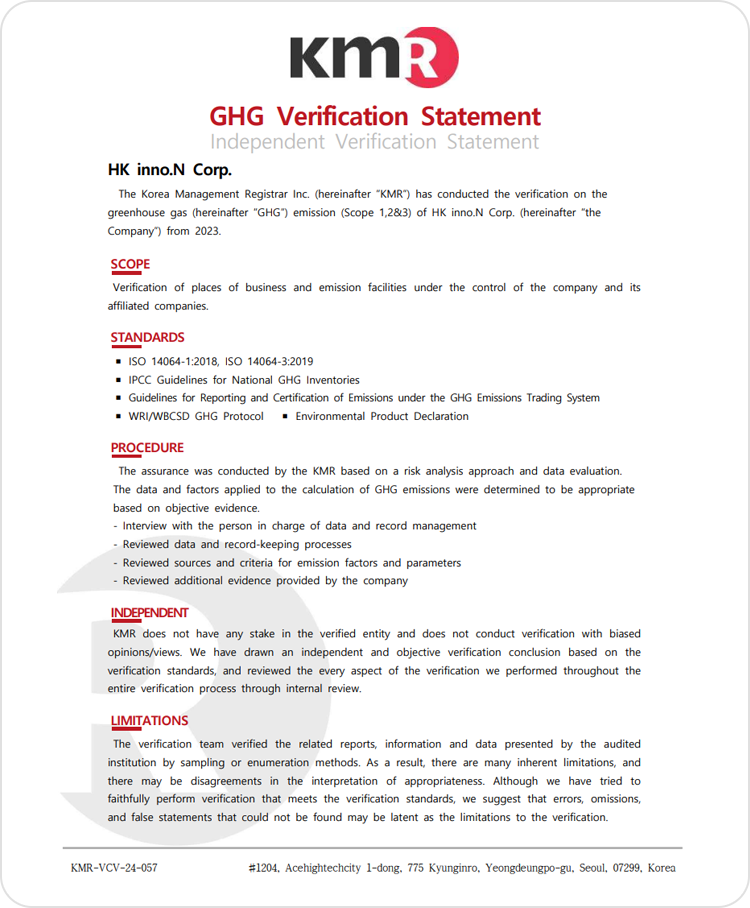

GHG Verification Statement

Certifications acquired

Certifications acquired